"I really appreciate the fact that Bosch Climate Solutions is very hands-on and focused on SMEs."

In this interview, Dirk Neumayer, Managing Director of Richard Neumayer GmbH, explains how he believes sustainability and competitiveness go together and why partners like Bosch Climate Solutions provide the necessary guidance.

2024 has been a successful year for Richard Neumayer GmbH. First, you won the TOP 100 award for "Innovation Success" and "Innovation-Promoting Top Management," and then your company was nominated for the German Sustainability Award. What does this mean for you?

Dirk Neumayer: Pioneering in our energy-intensive industry makes me proud. Our commitment to climate protection has attracted attention. We have been working hard on this for many years. One important step was our commitment to the Science-Based Targets Initiative (SBTi), which is linked to the Scope 1, 2 and 3 targets. We are already very successful in reducing our own emissions, and we are also paying close attention to reducing our carbon footprint in the upstream and downstream supply chain.

And you have further goals, which is why you are working with Bosch Climate Solutions.

Dirk Neumayer: Ever since I was a teenager, I have been interested in climate protection. Even then, I knew I wanted to do something to help preserve the planet we live on. At a climate conference, I spoke to the Härtha Group, a leading service provider for heat treatment processes and coating solutions. This led to the recommendation of Bosch Climate Solutions. We have been working together since late 2022, developing a climate strategy for our company. We are also laying the foundations for the Corporate Sustainability Reporting Directive (CSRD), the new EU directive on corporate sustainability reporting. I really appreciate the fact that Bosch Climate Solutions is hands-on and SME-oriented. In other words, they are pragmatic in their cooperation and don't overburden us with things that don't reflect our reality. It just fits.

What is your motivation to make your company a more sustainable one?

Dirk Neumayer: In my youth, events such as the Chernobyl nuclear disaster and the dying forests of the Black Forest had a strong impact on me. At school, teachers taught me about the findings of the Club of Rome and made me aware of the finite nature of resources. But I also saw that technological developments could help, for example when petrol was desulphurised and the forests recovered from acid rain. I realised that climate protection is also about innovation. This led me, among other things, to study physics.

After graduating, you joined the family company.

Dirk Neumayer: That was in 2011, and six years later I became the fifth generation of the family to run the company. At first, I couldn't believe how much energy and natural gas we were using. But that's where I saw an opportunity. With such an energy-intensive business, you have the potential to save a lot of resources.

What have you accomplished so far?

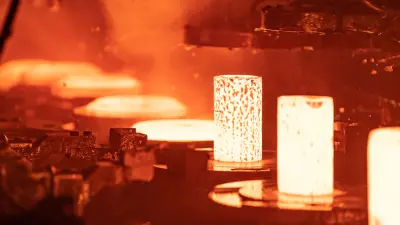

Dirk Neumayer: We have made great strides in material and energy efficiency, transforming forging and machining processes into intelligent workflows. For example, we use controlled cooling for heat treatment. Instead of cooling the metal parts after forming and then heating them again for further processing, we allow them to cool in a controlled manner in an insulated container. In my opinion, controlled cooling is a game changer. It is revolutionizing steel processing because it enables efficient and more sustainable forging processes. We also have very low gas consumption. As far as I know, we were the first large forge to switch to green electricity. Most of our processes are powered by electricity. We also generate our own electricity with our own wind power and PV systems. These approaches also have a cost advantage and increase our competitiveness.

So for you, sustainability reporting is not just a task to be done?

Dirk Neumayer: Exactly. Previously, I had a more physicist's view of CO2 reduction, in terms of effective reduction of greenhouse gas emissions. The SBTi commitment has broadened our view of supply chains. And with CSRD reporting, we are now moving to a new level. We are turning our actions into a strategy and a sustainability management system. This means that we will report regularly on our progress. Sustainability is part of our mission.

Why is it important to have a partner like Bosch Climate Solutions?

Dirk Neumayer: Because we want to do it right. Sure, there are guides or e-books and you can decide to do it yourself. But then I still don't know if I'm doing it right. The experience of Bosch Climate Solutions gives us a lot of confidence. What's more, with this support, you reach your goal much faster because you don't have to figure everything out yourself. Our core competence lies elsewhere. When it comes to SBTi, CDP and CSRD reporting, the consultants at Bosch Climate Solutions are the experts.

-

To achieve greater sustainability, material and energy efficiency has been strongly promoted and forging and machining processes have been redesigned. -

Why did you have to adapt your view of holistic reporting?

Dirk Neumayer: Most of all, I misjudged the time it would take. We invested six months. But it was worth it to follow the recommendation of Bosch Climate Solutions and have a comprehensive greenhouse gas balance drawn up. Their team ensured that we collected all the relevant data, that the data quality was good, and that the framework for transparent reporting was in place. In addition to production and climate data, information on social responsibility and the quality of corporate governance is systematically requested. We needed support, and we got it.

How do you make use of all the information you have today?

Dirk Neumayer: Our sustainability reporting meets regulatory requirements. We also inform customers, suppliers and the public about our work. Our customers benefit from our sustainability activities in meeting their own goals. Our suppliers can see why we ask them to commit to climate protection and how this affects the supply chain. But we also benefit from the information internally.

In what kind of way?

Dirk Neumayer: Today, I have a complete view of the company and the system in which we operate. This includes our supply chains and the needs of our customers. We also have detailed knowledge of individual operations. We look at these to see what additional changes and improvements can be made. We use this information to derive product design ideas and measure specific sustainability goals. And we are aware of the blind spots in production. For example, I underestimated the CO2 intensity of the sprays. Although this is small compared to our overall energy consumption, it is still high enough that we want to keep an eye on it. Thanks to the clean database, we can track developments and take action when the time is right.

How do your employees feel about the engagement?

Dirk Neumayer: Our employees are fully behind it. This is certainly due to the very sociable nature of Bosch Climate Solutions. The team gets people involved. For example, through joint workshops on climate protection. This is incredibly valuable and encourages all associates to become active themselves.

Do you have an example?

Dirk Neumayer: We cannot use controlled cooling for all components; some are cooled in forging tanks. Our apprentices worked with the technical manager and forging manager to figure out how to use this waste heat. The result is a large hot water tank that we use to preheat process media. In the winter, we also use it to heat our office building and a production hall. I think it's great that our apprentices came up with this idea together. They are proud of it and identify with it.

This demonstrates a strong awareness of the need to conserve resources.

Dirk Neumayer: Energy and resource management is part of climate change management. Even though we use 100% green electricity, we must and will continue to reduce our energy consumption to become even more energy efficient. Thanks to digitalization, we know exactly how much energy we need in production. We take into account the electricity we generate ourselves and our energy needs in our planning to schedule energy-intensive operations when we have a lot of our own electricity available. This summer, our employees proactively organized themselves so that both shifts could use almost all of the electricity from our solar system. Our customers also appreciate it when we can prove that their parts were forged using electricity from this solar system.

Can you explain that?

Dirk Neumayer: In production, we use intelligent system solutions and analyze large amounts of data collected during each step of the process. This allows us to monitor production in real time and save energy. We have a lot of meaningful data. With Bosch Climate Solutions, we have defined a strategically important goal: to use our sound database to calculate the CO2 footprint for each product. We are able to show our customers the development and composition of the CO2 footprint. This in turn helps our customers with their reporting.

How did Bosch Climate Solutions help you?

Dirk Neumayer: There were no established standards in our industry. But with the consultants' experience in the automotive sector, we were able to present our product carbon footprint. It is important to provide the highest level of professionalism and credibility in this area. That's why working with the experts is so valuable.

Are you ready to show off your first sustainable forged part?

Dirk Neumayer: And not only that. I can now show that production is also economical. Because we take a holistic view of sustainability. This includes the fact that we use the electricity we generate ourselves in production and that we also use less energy by utilizing residual heat. Sustainability has to be innovative.

Are your suppliers and customers getting the message?

Dirk Neumayer: Yes, the fact that we can do all this impresses a lot of people. Contributing to climate protection through innovation is a popular topic. At the same time, it strengthens our competitiveness. In any case, we are no longer just seen as a supplier to the automotive industry, but as an innovation partner.

What are your expectations for the future?

Dirk Neumayer: Suppliers like us are being asked to do more and more. And we demand more from our suppliers. So it's good when we inspire each other and push each other. It creates a dynamic and you are no longer a lone fighter, but you are in an exchange. This is how we launched the RE Industry Initiative, in which companies join forces to take control of the energy supply with renewable energies. As a very energy-intensive company, we want to consistently expand our contribution to climate protection. We cannot expect future generations to live in a world that goes beyond the 1.5 degree target. And we will succeed in limiting global warming.

About the company

Richard Neumayer GmbH is one of the leading companies in forming technology. With more than 400 employees, the Black Forest company produces forgings for machine and plant construction and the automotive industry. Today, more than one in ten of these forgings is used in electric vehicles. Dirk A. Neumayer is the fifth generation of the family to run the company. A physicist by training, he focuses on innovation and sustainability to offset the company's energy-intensive processes. In 2024, Richard Neumayer GmbH was nominated for the German Sustainability Award in the "Metal and Mineral Processing" category.