An ideal climate for great art

At the Museum Reinhard Ernst in Wiesbaden, Germany, even the technology is a work of art. To ensure perfect climate control at all times, the Bosch Energy and Building Solutions team implemented a high-end solution that sets new standards in the automation of intelligent buildings.

Opening in the summer of 2024, the Museum Reinhard Ernst in Wiesbaden, Germany, is a modern building of pure perfection - both inside and out. The museum is dedicated to abstract art. Selected works from the private collection of entrepreneur Reinhard Ernst, which includes more than 960 works from 1950 to the present, will be on display. Reinhard Ernst was able to secure the services of Pritzker Prize-winning architect Fumihiko Maki, whose designs include the Four World Trade Center, a tower of the new World Trade Center complex at Ground Zero in New York.

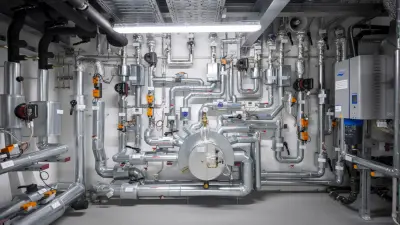

From the outside, the museum is a cube-shaped, gleaming white building that the people of Wiesbaden have dubbed the "sugar cube. The building has a total area of 9,700 square meters on several floors, including 2,500 square meters of exhibition space and an art depot. The building services are located on the lower level. “The building systems are so generously and elegantly installed that they almost look like art exhibits themselves,” remarks building automation expert Christian Disse, who has also ensured an ideal indoor climate in the Elbphilharmonie (“Elbe Philharmonic Hall”) in Hamburg.

„Special buildings, such as the Museum Reinhard Ernst, have different requirements - and that is where our ingenuity comes in.”

Building automation for optimal environmental conditions inside the museum

Achieving the perfect climate in a museum at all times and for all events is not a trivial task: even the slightest deviation from ideal conditions must be avoided, as it could result damage to valuable paintings and sculptures, as well as material losses. “All 10 of the exhibition rooms, the foyer, and the storage rooms are equipped with sensors that constantly monitor the temperature, relative humidity, and carbon dioxide content of the air,” explains Christian Disse. “The tolerances are extremely tiny, and the automatic system has to respond immediately and predictively to any factors or events that might disrupt these ideal conditions. These can be caused by, for example, fluctuating visitor flows or sudden changes in the weather.” His more than 30 years of experience have enabled him to design the building automation systems with sophisticated control algorithms and custom-tailored solutions to keep the indoor temperature and moisture constant at all times.

The specifications for room conditions may change depending on the exhibition. Currently, a room temperature of exactly 21 degrees Celsius at 50 percent relative humidity must be maintained. The allowed deviation is just two-tenths of a degree centigrade, so that the temperature remains within a narrow band between 20.9 and 21.1 °C. The relative humidity also has to be controlled so that it fluctuates by no more two percent, another technically demanding requirement. The foyer, the 10 exhibition rooms, and the depots are therefore monitored around the clock in real time. The building automation system also controls the heating system, which comprises an autonomously operating heat pump and a district heating substation. It ensures efficient use of the heat pumps and correct distribution of the energy flows. The interior of the building is climatized by heating and cooling elements in the floors, ceilings, and walls, all of which are controlled by the building automation system as needed. A total of 31 switch cabinet fields and 10 distribution boards spread around the building automatically control the power plant, two ventilation stations, central equipment and heating stations, and climatic conditions in the rooms and exhibit areas.

-

In the basement of the Museum Reinhard Ernst, a lot of space has been reserved for the building technology. (c) mre Helbig Marburger -

Customized solution for exceptionally high reliability requirements

The Bosch experts solved the problem of high operational reliability, especially with regard to constant room conditions, by means of extended programming of the automation equipment. The intelligent solution automatically recognizes when sensors are not working properly and bridges the time until the cause is eliminated by immediately switching to the next measurement technology. “It’s so incredibly important to maintain a constant indoor climate that we can’t just stop everything to fix a problem, like changing a wheel on a car when the tire is flat. Instead, we have to make corrections on the fly,” explains Christian Disse.

The automation system responds similarly if the climate control system or generator malfunctions and causes the heat pump to fail, for example. The Bosch team has developed and implemented predictive automation strategies for most of the critical scenarios that could conceivably occur in the museum. “When a customer is looking for a solution to meet a particular challenge, we come up with ideas for ensuring even greater operational reliability while talking with them,” says Disse. “One-of-a-kind facilities like the Reinhard Ernst Museum have special needs, which calls for our ideas and ingenuity. Thanks to our many years of experience, we’re able to come up with innovative solutions that fit the bill for our customers. With an owner who is as tech-savvy as Reinhard Ernst, this is a very enriching exchange.” Until just a few years ago, the entrepreneur led two globally successful mechanical engineering companies.

About our expert Christian Disse

Christian Disse, an electrical engineer and expert on complex automation solutions, has been working in the field of building automation for more than 30 years. He played a key role in drawing up and implementing the detailed plans for the systems in the Museum Reinhard Ernst. While doing so, in addition to meeting routine building automation requirements it was important for him to reliably ensure constant climatic conditions to protect the valuable artworks kept there. Disse draws on deep expertise in measurement and control technology and in programming complex automation solutions. He has also demonstrated his highly specialized knowhow and abilities while coding the complex control solutions that were implemented in the Elbe Philharmonic Hall, among other projects. What he enjoys most is tinkering to find the best ways to meet clients’ wishes. “But at the end of the day, I need the whole team backing me up. What I’ve programmed doesn’t come to life until they’ve connected and configured the field devices”.

Cross-vendor integration via bus technology

To seamlessly monitor conditions and ensure reliable climate control in the museum and its rooms, the team from Bosch Energy and Building Solutions integrated more than 600 almost invisibly installed sensors and actuators in the museum’s rooms. In addition to measuring the temperature, humidity, and carbon dioxide content, these control water and air feed and report operating states and other relevant building data to automation systems from Bosch. More than 1,600 hardware data points and around 2,700 communication points have been networked almost completely wirelessly using bus technologies such as the Modbus client/server data communication protocol. This makes it possible for data to be exchanged on current states and correction values across vendors and sectors in real time in the larger context of the building’s other technical systems. “This solution lets us interconnect all of the field devices, control equipment, and technical systems without the need for any additional interfaces,” says Christian Disse. “The system is also straightforward to scale up and down.”

-

In the first four weeks of its opening, 20,000 art and architecture enthusiasts visited the Reinhard Ernst Museum. (c) mre Helbig Marburger -

Building management software for reliable and efficient operation

All of the building’s systems are easy to control via the proprietary WEBVISION 5 building management software from Bosch Energy and Building Solutions. The building’s technical systems can be watched, controlled, and monitored on a screen. Software for intelligent analysis also helps the operator and technical team continually optimize ongoing operation of the building. Because all of the power meters are linked via a data bus, it is easy to use the building management software to visualize, analyze, and evaluate consumption.

The Reinhard Ernst Museum hosts not only exhibitions but also a wide variety of other events that attract large numbers of visitors. Changing uses of climate-sensitive areas normally causes headaches for operators and facility managers. But the Bosch solution is a shining exception, thanks to its ability to automatically support different scenarios. These are defined in advance by programming the operating states in the building that are needed for one-off or recurring situations or events. “Then all it takes is for an employee to select an event by clicking on it with the mouse, and everything happens automatically,” explains Disse. In such a unique building as this one, nothing is left to chance. The integrated WEBVISION 5 report management system also makes it possible to securely communicate any disruptions or deviations in building systems, also from external instances such as security systems.

Optimal building performance even from a distance

When required, the museum’s team receives fast support from Bosch’s team of experts, who are able to access the system from afar. A remote diagnosis can quickly shed light on what is going on – and, often enough, eliminate the need for on-site intervention. But if it is necessary for a technician to head for the museum in Wiesbaden, it is no problem to take the right replacement parts along. This and other services enable optimal building performance and sustainable operation, both today and in the future.